Knowledge about CSQCC’s biological odor removal technology

Knowledge about CSQCC’s biological odor removal technology

CSQCC Biological Odor Removal Introduction:

The CSQCC biological deodorization technology developed by our company is based on German-developed technology. Its operational principle is straightforward: The front-end employs a spray humidification system to break down water-soluble odor molecules in the air. Subsequently, a biofilter bed processes residual odor compounds in the exhaust gas. As these odor molecules consist of diverse organic substances, they undergo microbial absorption and degradation within the biofilter bed. This comprehensive treatment ensures that all discharged air meets emission standards.

The treatment system is suitable for urban sewage treatment plants, urban feces treatment plants, all kinds of chemical plants and other environments with relatively poor conditions. The system is not suitable for the treatment of odorous gas with temperature higher than 80℃. Because the temperature is too high, the microorganisms in the biofilter field can not survive, so as to achieve the expected effect.

The standout advantage of biological odor control systems lies in their microbial degradation technology for organic pollutant removal. The system’s success hinges on creating optimal microbial habitats. By utilizing natural organic fillers that inherently serve as carbon sources, it enables sustained microbial growth even when nutrient levels are low in odorous gases. Unlike conventional odor control methods requiring additional nutrient supplementation during treatment, this approach eliminates unnecessary costs while maintaining effective odor management.

Photo illustration of biological deodorization equipment:

Glass fiber reinforced plastic tank biofilter bed Secondary spray humidification tower

Integrated humidification tower Concrete pool biological deodorization filter bed

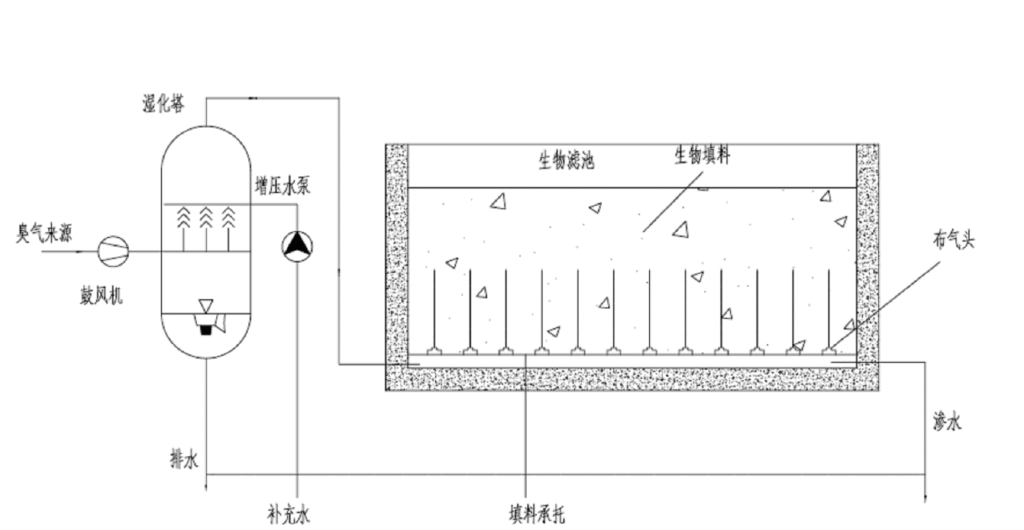

Flow diagram of CSQCC biological deodorization system:

As can be seen from the flow chart below:

First, the odor to be treated is collected by the induced fan, and then it is injected into the spray wetting tower, and then discharged into the biofilter. The odor passes through the biofilter bed, and then further degraded by microorganisms, and finally discharged.

Among them, the spray water in the spray humidification tower can be recycled, so it is generally used by a circulating pump for recycling, and only needs to change the water regularly. The fresh water is replenished through the water replenishment solenoid valve. Because the degraded odor molecules and some dust in the odor will form deposits deposited in the humidification tower.

Because the fan generally has a wind pressure of more than 2000Pa, the humid gas in the humidification tower will take part of the water vapor to the biofilter, which is just enough to supplement the water of the biofilter bed to maintain the needs of microorganisms, so the biofilter does not need to be replenished during operation.

Technical parameters of biological deodorization equipment:

The design of the biological deodorization system is based on the gas volume and odor concentration of the site. Therefore, there is no fixed size in the design, and it needs to be calculated according to the gas to ensure the discharge standard.

The selection of fans is determined based on the actual air volume generated at the site. However, in general design practices, odor removal for large areas (such as an entire workshop) typically requires a ventilation rate of around 3 times per hour. For smaller areas (like equipment interiors or grating channels), the recommended ventilation rate is approximately 8 times per hour.

In addition, the design height of the biofilter should not be greater than 1.5m. Because the higher the height of the filter bed, the greater the pressure on gas penetration, and the corresponding wind pressure is greater, and too high a height, the filter material is easy to “waste” during long-term operation.

The selection of other circulating water pumps is designed according to the actual nozzle flow in the humidification tower. If the owner has high design requirements and the odor concentration is very high, an activated carbon adsorption tower is added behind the biofilter bed, which is generally made of PP material.

In the design, it is necessary to design according to the actual available floor area of users. The size of the biofilter bed can be designed according to the floor area, and it can be designed into different length and width proportions or double or multi-layer structure. For details, please communicate with our technical staff.

Our company provides high quality and stable products, including reverse osmosis system, sludge dewatering machine, mechanical grille, dosing device, electrical control cabinet, etc., our professionals will provide you with installation, commissioning, operation, and follow-up maintenance services to help you solve problems!

Yixing Shenghe Environmental Protection Co., Ltd.

IPv6 network supported