Sludge Dewatering In Wastewater Treatment

Sludge dewatering in wastewater treatment is a crucial part of the whole sludge treatment process. Its purpose is to further reduce the concentrated sludge and create conditions for subsequent disposal or resource utilization.

The following is a comprehensive analysis of sludge dewatering in wastewater treatment:

1. Importance of sludge dewatering:

In the process of wastewater treatment, a large amount of sludge with high water content (primary sedimentation sludge, residual activated sludge, etc.) will be produced. The initial water content is as high as 97%-99.5%, which means that most of the components in the sludge are water.

At this time, it is necessary to dehydrate the sludge. After dehydration, the volume of the sludge will be reduced to 1/5 of the original, and the weight will also be greatly reduced, thus reducing the subsequent transportation and disposal costs.

At the same time, the organic matter in the sludge will be reduced after dewatering, so it is not easy to rot and smell.

Some harmful substances will also be removed, providing favorable conditions for subsequent reuse such as composting and incineration for power generation.

The moisture content of clay cake is the key index to determine whether it can be recycled or not.

2. Main process of sludge dewatering:

Sludge dewatering is not a single equipment, but a set of system process, mainly including:

• Sludge conditioning: This is the key pretreatment step before dewatering, aiming at changing the physical and chemical properties of sludge particles, destroying their colloid structure, releasing internal water, and improving dewatering performance.

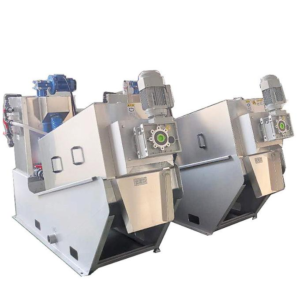

• Mechanical dehydration: the use of mechanical equipment to apply external force (pressure, centrifugal force, etc.) to the adjusted sludge to achieve solid liquid separation. This is the current mainstream method.

• Mud cake disposal: The mud cake formed after dehydration is transported to different final disposal sites according to its properties.

3. Comparison of mainstream mechanical dehydration equipment:

Here is a comparison of the three main types of dehydration equipment, of which the belt dewatering machine is one of the most widely used.

• Strip Dewatering Machine: Sludge is sandwiched between two filter belts, undergoing gravity dewatering, wedge zone pre-pressing, and high-pressure roller pressing. This system offers large processing capacity, low operating costs, simple operation, easy maintenance, and reduced energy consumption. However, it requires significant floor space, consumes substantial rinse water, and may experience belt misalignment needing precise adjustments. Additionally, its relatively open design could potentially generate odors.

• Plate and Frame Dehydrator: A pump forces sludge into a filter chamber containing multiple filter plates and frames. Under high pressure, water is filtered through the cloth to be discharged. The output features minimal solid content, high-quality cake formation, reduced chemical dosage, and a sealed operational environment. However, it operates intermittently with extended single-cycle durations, requires large installation space, incurs higher costs when automated, and presents challenges in filter cloth replacement.

• Centrifugal Dehydrator: This equipment utilizes centrifugal force generated by high-speed rotating drums to separate solids from liquids based on density differences. It features fully enclosed operation, environmental cleanliness, compact footprint, high automation level, and continuous operation capability. However, it has notable drawbacks including high energy consumption, expensive equipment costs, stringent maintenance requirements, sensitivity to sludge fluctuations, and significant noise levels.

4. Factors to be considered in the selection of dehydration equipment:

• Sludge properties: organic matter content, viscosity, fiber material content and so on are the primary consideration factors.

• Treatment scale: large sewage plants often use belt machine or centrifuge, small and medium-sized or decentralized treatment may choose spiral machine.

• Dewatering moisture content requirements: when the dryness is extremely high (such as for incineration), plate and frame filter press is the first choice.

• Investment and operating costs: including equipment investment, power consumption, drug consumption, maintenance costs and labor costs.

• Site conditions: floor area, floor height, environmental requirements (e.g., whether to be closed and deodorized).

5. Summary:

Sludge dewatering is an indispensable “back-end” link in wastewater treatment plants, and its effect is directly related to the operation cost and environmental benefit of the whole plant.The choice of dehydration process and equipment should be determined after comprehensive technical and economic comparison according to the specific sludge characteristics, treatment requirements and economic conditions.

Our company provides high quality and stable products, including reverse osmosis system, sludge dewatering machine, mechanical grille, dosing device, electrical control cabinet, etc., our professionals will provide you with installation, commissioning, operation, and follow-up maintenance services to help you solve problems!

Yixing Shenghe Environmental Protection Co., Ltd.

IPv6 network supported